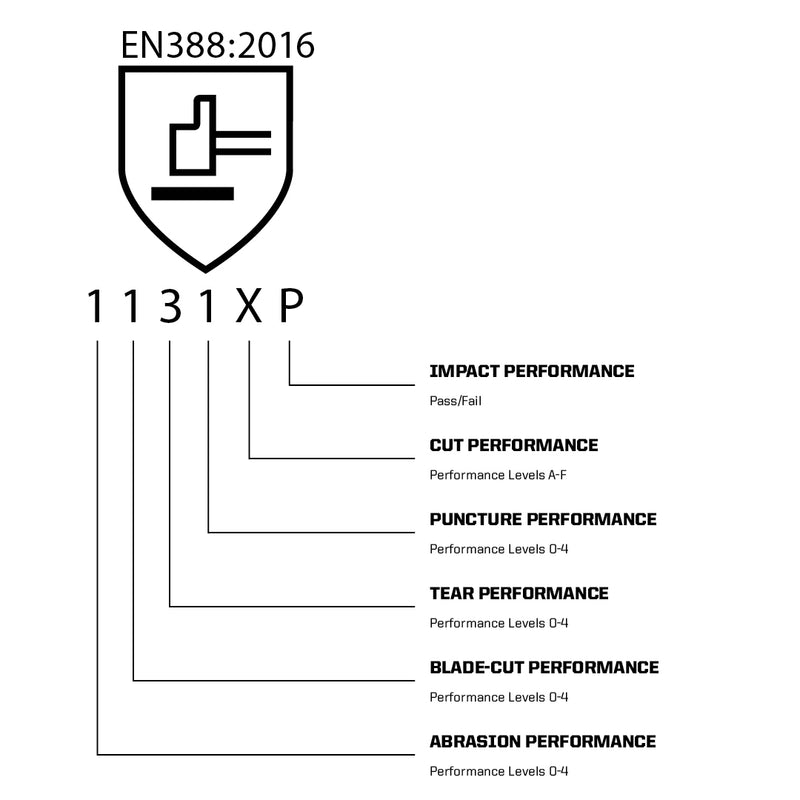

EN 388 is a European standard for protective gloves against mechanical risks. It was established to provide a consistent method for evaluating the performance of gloves in protecting against abrasion, cut, tear, and puncture. The standard assigns a performance level for each of these risks, as well as for impact protection, and is represented by a series of four or five digits on the glove, or on its packaging, that indicate the level of performance.

The four or five digits are the results of the different tests performed on the gloves, each digit corresponds to a specific test:

- The first digit represents abrasion resistance, it ranges from 0 to 4, with 4 being the highest level of abrasion resistance.

- The second digit represents cut resistance, it ranges from 0 to 5, with 5 being the highest level of cut resistance.

- The third digit represents tear resistance, it ranges from 0 to 4, with 4 being the highest level of tear resistance.

- The fourth digit represents puncture resistance, it ranges from 0 to 4, with 4 being the highest level of puncture resistance.

- If the glove has a fifth digit it represents impact protection, it ranges from 0 to 2, with 2 being the highest level of impact protection.

EN 388 is not a guarantee of protection, rather it is a method for comparing the performance of different gloves. It is important to note that the standard does not take into account other factors such as the fit, comfort, dexterity and durability of the glove. The standard also does not include any test for chemical or biological hazards, or for electric arc or thermal risks.

In summary, the EN388 standard is a way to compare the mechanical performance of gloves and to provide a consistent method for evaluating their protection against abrasion, cut, tear, and puncture, as well as impact protection (if applicable). It's important to note that it does not take into account other factors such as chemical or biological hazards, electric arc or thermal risks.